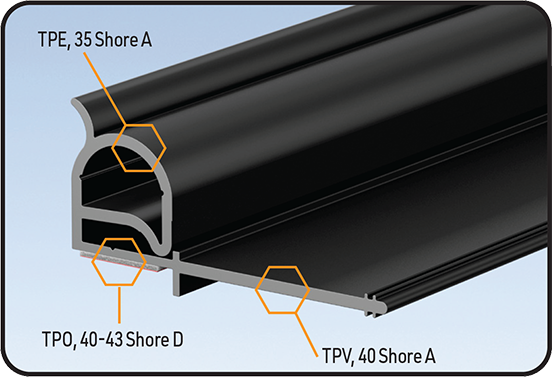

Trim-Lok specializes in multi-material co-extruded profiles, seamlessly combining a variety of materials—including dual durometer designs—into a single, high-performance product. This advanced process harnesses the unique properties of each material—such as flexibility, cushioning, strength, and durability—to create versatile, cost-effective solutions.

Co-extrusion also offers the advantage of reducing the number of parts in an assembly by consolidating multiple functions into one part, optimizing production and boosting efficiency. Trim-Lok has the expertise to extrude parts with 2, 3, 4, or even 5 materials, providing tailored solutions for a wide range of applications.

|

Advantages of Co-Extrusion

- Multi-material functionality – Combines different materials into a single part, allowing you to integrate rigidity, flexibility, sealing, and dual durometer designs in one component.

- Enhanced performance – Tailored material placement can improve resistance to weather, chemicals, abrasion, or vibration compared to single-material parts.

- Cost and assembly efficiency – Reduces the need for multiple components, fasteners, or secondary assembly steps, saving time and lowering production costs.

- Design versatility – Enables complex shapes, colors, profiles, and dual-durometer combinations that would be difficult or impossible to achieve with separate parts.

- Improved durability and lifespan – Optimized material bonding reduces wear, leakage, and failure points, extending the service life of the part.

|